963

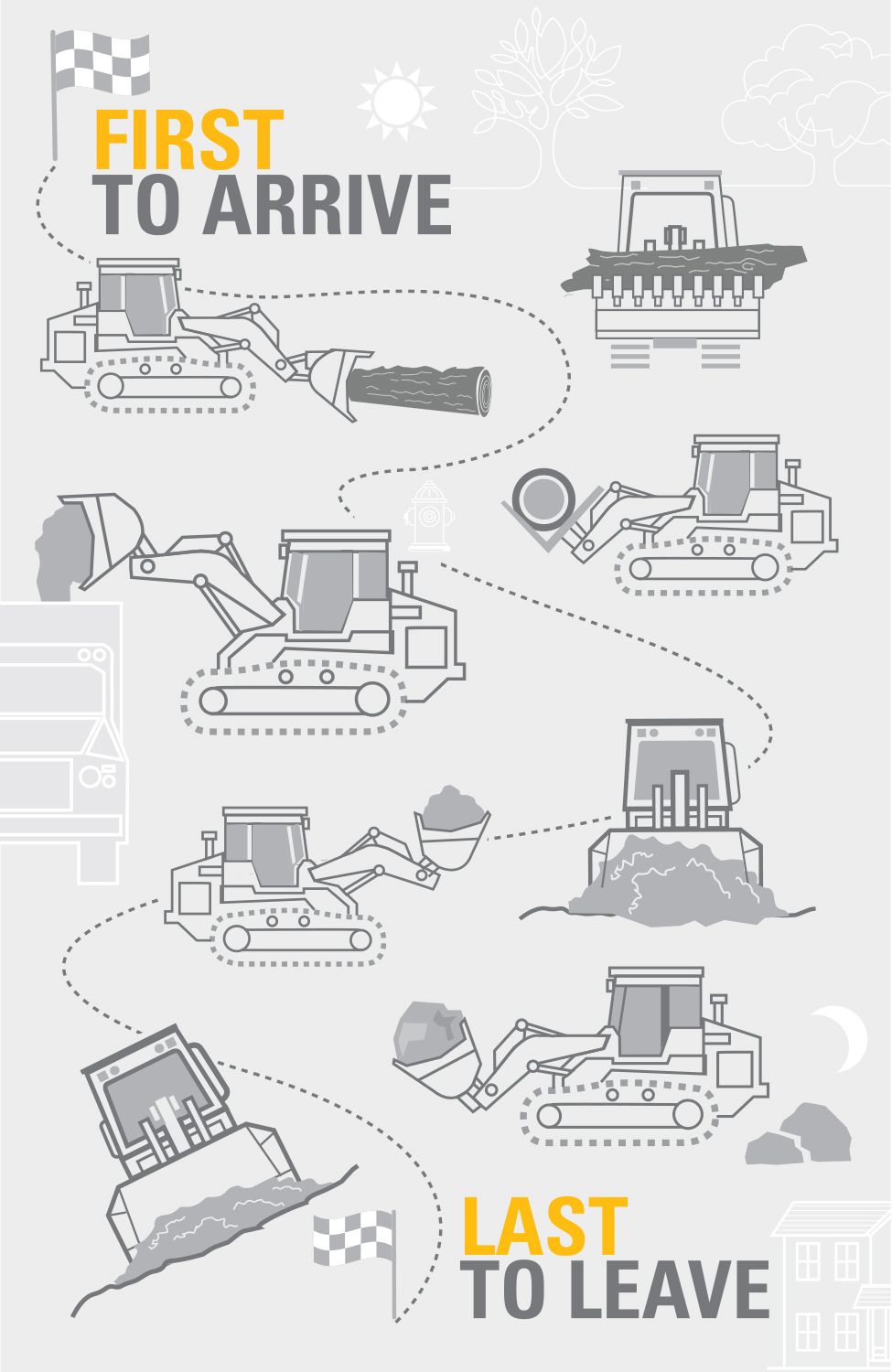

Save money and transport time with one rugged machine that does it all – land clearing, digging, grading, truck loading, slope work and more. Crawler loaders give you lower ground pressure and better traction so you can start the job sooner, and work longer, in all kinds of underfoot conditions. Cat® Track Loaders give you all this, plus outstanding performance and fuel efficiency.

Flywheel Power

202 HP

Engine Model

Cat C7.1

Net Power - ISO 9249/SAE J1349

202 HP

Specification

Value

Flywheel Power

202 HP

Engine Model

Cat C7.1

Net Power - ISO 9249/SAE J1349

202 HP

Net Power - ISO 9249 (DIN)

204 mhp

Emissions

Meets U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, China Nonroad Stage IV, Japan 2014 emission standards or India Bharat Stage III, Eurasian Economic Union Stage IIIA, UN ECE R96 Stage IIIA emission standards, equivalent to U.S. EPA Tier 3/ EU Stage IIIA.

Note (1)

Cat U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, China Nonroad Stage IV, Japan 2014 engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester)*; 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Cat engines meeting Eurasian Economic Union Stage IIIA, UN ECE R96 Stage IIIA emission standards, equivalent to U.S. EPA Tier 3/ EU Stage IIIA, are compatible with diesel fuel blended with the following lower-carbon intensity fuels up to: 100% biodiesel FAME (fatty acid methyl ester)**; 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. *Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (For use of blends higher than 20% biodiesel, consult your Cat dealer). **For use of blends higher than 20% biodiesel, consult your Cat dealer.

Note (2)

Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions Module (when equipped) and alternator. Advertised power is tested per the specified standard in effect at the time of manufacture.

Specification

Value

Operating Weight

44881 lb

Specification

Value

Fuel Tank

84.5 gal (US)

DEF Tank

4.2 gal (US)

Specification

Value

Operating Weight

44881 lb

Width of Standard Shoe

22 in

Ground Contact Area

4900 in²

Ground Pressure

9.1 psi

Specification

Value

Operating Weight

50181 lb

Width of Standard Shoe

31 in

Ground Contact Area

7136 in²

Ground Pressure

7 psi

Specification

Value

Operating Weight

45549 lb

Width of Standard Shoe

22 in

Ground Contact Area

4900 in²

Ground Pressure

9.2 psi

Specification

Value

Overall Machine Length*

275.6 in

Machine Height - Top of Cab

130.9 in

Height - Top of Stack

115.7 in

Overall Machine Height - Bucket Fully Raised

212.7 in

Overall Machine Width without Bucket: With Standard Tracks - 550 mm (21.6 in) Shoes

94.5 in

Note

*With General Purpose bucket and extra duty teeth.

Specification

Value

Track Gauge

72.8 in

Track on Ground

100 in

Track Rollers/Shoes - Each Side

7 / 38

Specification

Value

Capacity - General Purpose

3.2 yd³

Capacity - Multi-Purpose

2.6 yd³

Capacity - Performance Series

3.7 yd³

Width - General Purpose

101.2 in

Width - Multi-Purpose

101.3 in

Width - Performance Series

105.2 in

Specification

Value

Air Conditioning

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.1 kg of refrigerant which has a CO2 equivalent of 1.573 metric tonnes.

- Track loader power, traction and agility mean you can use one machine and one operator to do everything from clearing the site to installing utilities and finishing around buildings.

- Fusion™ Quick Coupler option lets you make fast attachment changes with a wide range of tools like forks, buckets, etc. from wheel loaders and other Fusion compatible machines.

- Bucket/tooth, undercarriage, track shoe and attachment choices help you equip your machine for optimal performance in your applications.

- Purpose-built Waste Handler, Low Ground Pressure (LGP), Ship Hold and Steel Mill configurations stand up to the toughest tasks.

- 963 uses up to 10% less fuel per hour than the previous model.

- Performance Series bucket option boosts productivity up to 20% compared to General Purpose bucket.

- Get more power to the ground under load with 15% more peak torque.

- Cat Payload* technology delivers precise bucket load information with on-the-go weighing. More accurate loading reduces cycle times to help save time, labor and fuel costs.

- Advansys™ bucket tips are built to give you maximum productivity and the lowest bucket lifecycle cost for your toughest applications.

- Smoother implement and steering response, and improved steering performance provide more controllability.

- Load sensing hydraulics and position sensing cylinders offer precise, responsive performance.

*Not legal for trade.

- Comfortable cab and an intuitive 10-inch (254 mm) touchscreen dash display to help make the job easier.

- Standard High Definition rearview camera shows prominently in the main display.

- Slope Indicate helps make operation easier by showing machine mainfall and cross slope right on the display.

- Enjoy operator comforts like suspension seat and adjustable armrests and controls.

- Choose either joystick or two-lever implement controls to match operator preference or application.

- Speed/steering control choices include either a joystick or a v-lever and foot pedals.

- Set implement response - fine, normal, coarse - to match operator preference or application.

- Emissions reduction technology (when equipped) is designed to work in the background, with no action required from the operator.

- Excellent visibility to the bucket and all around the machine enhances safety and helps operators work more confidently.

- Handles and steps help operators climb on and off the machine more easily, from the front or the back of the tracks.

- Standard rear vision camera enhances visibility behind the machine.

- Seat belt indicator gives an alarm and registers fault code through Product Link if the operator fails to buckle up, enhancing job site safety.

- Ergonomics, a quiet engine and low-effort controls help lessen fatigue, so operators are better able to remain fresh and focused.

- Equip your loader from the factory to take on extra-challenging tasks like soft footing, waste handling ship hold and steel mill work.

- For added flotation and traction, or work in more sensitive ground conditions, choose a Low Ground Pressure (LGP) loader with wider tracks.

- Waste Handler configuration is a versatile machine for loading, sorting, excavation and spreading cover, and well suited to the landfill or transfer station. Specialized guarding, striker bars and seals help protect the machine and components from impact and airborne debris. Enhanced Cleaning Package reduces cleaning time, adds machine protection and increases compaction.

- Traction, high reach and machine balance make track loaders ideal for working in ship holds and port handling duties. Specialized guarding and seals help protect the machine, while attachments like coal buckets and trim blades help you get the job done.

- Your track loader can be factory equipped with a heat-resistant cab, high-temperature guarding and other features to help protect the machine and operator in high-temperature steel mill work.

- Designed to help you take care of routine maintenance and get back to work.

- Grouped service points located behind large access doors.

- Daily grease points in easy reach at ground level.

- Service mode in the operator display shows hydrostatic and implement pressure for easier troubleshooting and servicing.

- Demand fan provides efficient cooling plus easy fold-down service access.

- Handy bracket holds a shovel for quick undercarriage clean-out.

- Tilt cab and convenient service access points for easier maintenance and repair.

- Diesel Particulate Filter in the Clean Emissions Module (when equipped) designed to work for the life of the engine without needing to clean or replace the filter.

- Product Link™ collects machine data that can be viewed online through web and mobile applications.

- Access information anytime, anywhere with VisionLink® and use it to make informed decisions that boost productivity, lower costs, simplify maintenance, and improve safety and security on your job site.

- The Cat App helps you manage your assets, at any time, right from your smartphone. See fleet location and hours, get critical required maintenance alerts, and even request service from your local Cat dealer.

- Remote Troubleshoot saves time and money by allowing your Cat dealer to perform diagnostic testing remotely.

- Remote Flash updates on-board software without a technician being present, at a time that is convenient for you, potentially reducing update time by as much as 50%.